“The Timatic® PE ATEX series extractors are technologically advanced machines dedicated to the extraction of active ingredients from medicinal plants and herbs by using, in addition to the standard solvents, potentially flammable and/or explosive solvents.

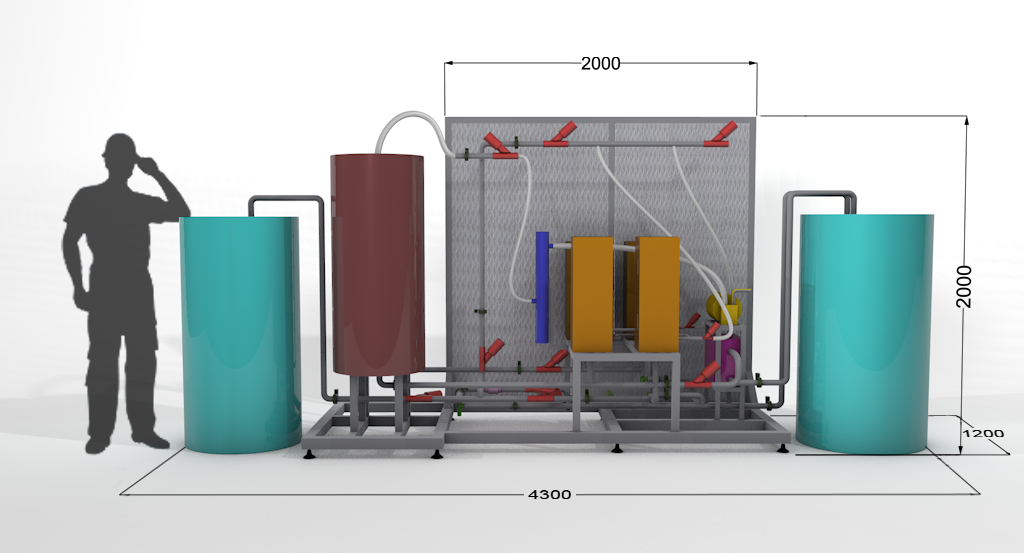

They are modern, compact and most importantly safe. They provide an automated alternative to traditional extraction systems, with the added advantage of being able to use a very wide range of solvents in a single machine.

They allow extractions from fresh or dried products without any pre-treatment, obtaining in a very short time a finished product that keeps all its nutritional, bio-functional and organoleptic properties.

The fully programmable operating cycle, automatically run by a PLC that meets all Industry 4.0 requirements, repeatedly alternates phases of pressure/expansion of the solvent in the biomass with phases of percolation and recirculation through the biomass itself, resulting in the best possible plant extract.”

1) Emergency button

2) LCD touch screen monitor

3) Extraction chamber

4) Solvent suction

5) Extract retrieval

6) Passive piston

7) Active piston

8) Air connection

9) Crank winch

10) Lifting winch

Innovative ATEX compliant equipment for solid/liquid extraction of active ingredients from phytoextracts using a wide range of solvents, including flammable and/or potentially explosive solvents, in absolute safety.

Ideal equipment for a wide range of applications, for analytical and research laboratories, university laboratories, pharmacies, small and large manufacturing industries.

- 2 lt

- 10 lt

- 50 lt

- 100 lt

- 200 lt

- 200 lt

- + 200 lt

- Category 2/3/- equipment with ATEX certification (2014/34/EU) to safely handle a wide range of flammable and/or potentially explosive solvents such as: Pentane, Hexane, Cyclohexane, Acetone, Butanone (MEK – Methyl Ethyl Ketone), Ethanol, Dichloromethane

- Can be certified by IECEx to accelerate additional local certifications for non-European customers, such as HAZLOC (North America), CCC Ex (China), and achieve full compliance

- Manufactured using only the best chemical resistant components available on the market, such as Aisi 316/304, PTFE and FFKM

- Fast extraction time compared to traditional extraction techniques

- Extraction control via a fully customizable PLC

- Reproducibility of past extractions (10 formulas can be stored and retrieved if needed)

- Machine fully compliant with Industry 4.0 standard

- Production of pre-filtered extracts down to 5 μm obtained in a hermetically sealed environment and under anaerobic conditions

- Multiple extraction principles (recirculation, percolation and pressure/expansion) combined in one machine

- “Winterized” versions (on request) allow the extraction temperature to be set from room temperature (max. 35 °C) to below 0 °C (min. – 20 °C), for targeted cryogenic extraction of specific biomass components

- Possibility to use nitrogen in the solvent discharge phase

- Fully automatic work cycles: operator intervention is limited to the loading and unloading of the product

- Reduction of raw material storage and streamlining of finished product stocks