• The FC series extractors are used to extract natural oils, aromas, essences, perfumes and other natural substances from many products of the plant kingdom (flowers, roots, leaves, etc…).

• The extracts obtained can be used in many sectors: cosmetics, food, pharmaceuticals, especially for the creation of new products.

• The extraction process uses R134a gas which, under specific conditions, can extract natural oils and all volatile compounds of low molecular weight.

• The extraction takes place without any pre-treatment of any type of biomass (fresh or dried product).

• The whole extraction process is fully automatic and run by a powerful processor that controls the settings and variables during the different steps, displayed on the touch screen.

• Throughout the process, the gas is continuously filtered and then fully recovered and reused later, keeping it in anaerobic conditions of absolute hygiene.

• R134a gas is a safe solvent: it is approved by the FDA, the US government agency that regulates pharmaceutical products, and according to Directive 2009/32 EC of the European Parliament, which authorizes its use in the production of foodstuffs.

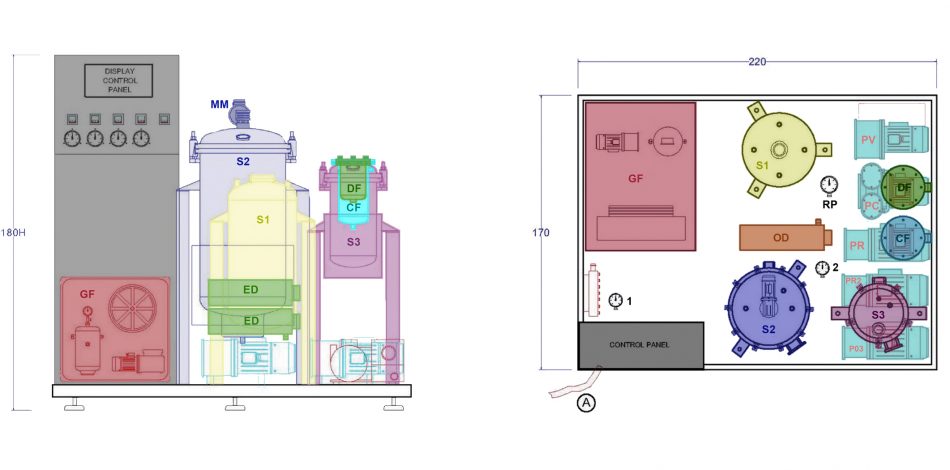

S1) Gas storage tank

S2) Extraction chamber

S3) Evaporator

MM) Mixing motor

PR) Gas transfer pump

Po3) Hot oil pump

PR2) Recirculation pump

PV) Vacuum pump

PC) Diaphragm pump

GF) Refrigeration unit

CF) Activated carbon filter

DF) Particle filter

OD) Heated oil tank

RP) Pressure reducing valve

1) air pressure regulator

2) air pressure regulator for coils

Extractors for small, medium and large laboratories to extract natural oils, aromas, essences, perfumes and many other natural substances.

Fields of applications

- Extraction of natural oils, aromas, essences, perfumes and other natural substances for the cosmetic, food, pharmaceutical, chemical and fragrance industries

- Extractions without pre-treatment of any type of fresh or dried biomass, flowers, leaves, seeds, bark, roots, etc…

- Extractions from concretes, liquids and all kinds of products

- Extract obtained: very pure and rich natural oil, useful for the creation of new lines of products, aromas and perfumes

- 10 lt

- 50 lt

- 100 lt

- 500 lt

- 1000 lt

- FC 10 Natural oils extractor with 10 liters extraction chamber

- FC 50 Natural oils extractor for small scale production with 50 liters extraction chamber

- FC 100 Natural oils extractor for small and medium production with 100 liters extraction chamber

- FC 500 Natural oils extractor for large scale production with 500 liters extraction chamber

- FC 1000 natural oils extractor for large-scale production with a 1000 liters extraction chamber

- Extraction process using R134a gas to extract natural oils and all kinds of low molecular weight volatile compounds

- Extraction in hermetically sealed containers, with programmed and controlled temperatures and pressures, with a neutral PH

- Maximum safety and hygiene: extracts obtained in anaerobic conditions

- Total and automatic recovery of gas for continuous filtering and reuse throughout the process

- Touch screen for real time visualization of all the functions and variables of the process:

- Extraction time

- Temperature settings

- Pressures in the different tanks

- Solvent flow and weight

- Multiple programs can be stored for repeatability purposes

- Special windows to monitor key stages of the process: extraction, oil and gas separation and gas retrieval.