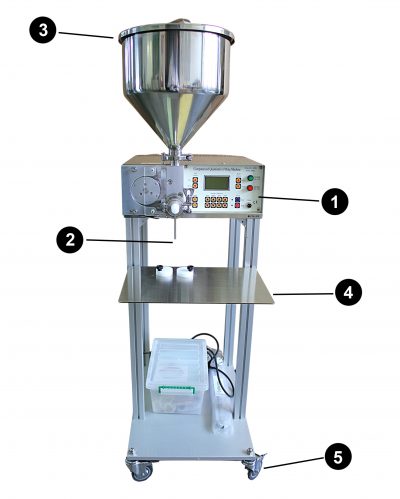

1) Control panel

2) Product outlet

3) Product loading funnel

4) Support structure

5) Swivel wheels

2003 FILLING MACHINES

Computerized Quantitative Filling Machine

The 2003 Filler series filling machines are semi-automatic and equipped with a high precision peristaltic pump for filling liquid, semi-liquid, viscous, dense and creamy products.

With the heated hopper option, you can use the 2003 Filler Series fillers for any type of processing, including the heat processing required for very dense products that require constant, controlled temperatures.

All parts that come in contact with the products can easily be disassembled for cleaning and disinfection or sterilized in an autoclave for safe and effective cleaning.

Features

- Double pumps are designed for enhancing the filling capability and reducing the impulse.

- Filling capacity ranges from 0.4 ml up to 4000 ml per fill.

- Capable of handling liquid/viscid materials with viscosity from 0 up to 100,000 cp.

- Filling speed ranges from 10 ml up to 200 ml per second..

- Materials are metered precisely by computerized control system, digitalized setting of parameters, LCD display, and AC servomotor.

- Able to transmit materials of liquid/viscid form at room temperatures or warmer.

- Peristaltic pump adopted ensures zero percent material transformation during process.

- Patent designed Suck Back function ensures no dripping for each fill.

- Medical/food grade pump pipe guarantees contamination-free transmission.

- Top grade industrial stainless steel (no. 306) is utilized for all major parts and accessories.

- Different sized filling pipe heads are designed and provided to fill bottles of small sized openings with ease.

- Intake hoses, with strengthened texture, are supplied to suck liquid type materials from containers other than the hopper.

- Interchangeable usage of “Auto”, “Manual”, and “Pedal” functions optimizes production.

- Connecting with conveyance equiment completely achieves automatic process and labor saving.

- 10 minutes effortless cleaning procedure totally eliminates excess labor.

- Suitable for pharmacy, foods and cosmetics quantitative dispensation.

Technical Specifications

- Dimension of Main Machine: L x W x H

60cm x 42cm x 104cm (2 x 1’5″ x 3’5”) - Net Weight of Main Machine: 55kg (122 lbs)

- Power Supply: Monophase 220V 50/60 HZ

- Hopper Size: 50liter

- Speed:10~30 bottles per minute

Sectors of use

- Pharmaceutical products

- Cosmetics industry

- Food industry

- Chemical industry